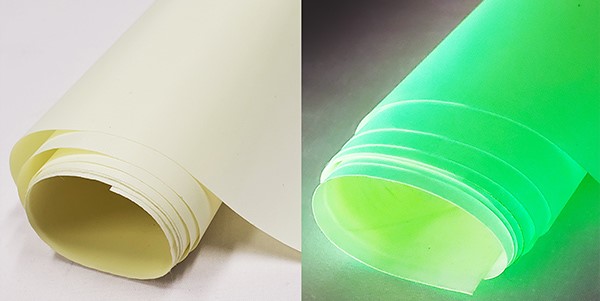

In recent years, designers have been turning to glow in the dark fabric, also known as photoluminescence or phosphorescent material, to add a touch of enchantment to their creations that will appeal to children and adults alike.

Fabrics that emit a fluorescent glow when exposed to UV light or other visible ambient light are called “glow in the dark.” However, reflective textiles are all the rage nowadays for style and security.

What Makes Glow-In-The-Dark Cloth So Effective?

We opted for aluminum silicate because of its superior luminosity, extended afterglow, reliable performance, and lack of radioactivity. However, aluminum silicate can emit light for more than 8 hours, whereas sulfide can only do so for 30 minutes.

Why Is Reflecting Material So Effective?

Micro glass beads are inserted on adhesives and glued to a base fabric to create the reflective material. Micro glass beads have sizes as small as powder and range from 20 m to 100 m. A unique coating method partially covers the micro-glass dots with aluminum or other optical materials.

As a result, when illuminated by a car’s headlight, the reflective material will flash a brilliant display of silver, multicolored, or rainbow-hued light, making it visible up to 200 meters away.

Methods for Seeing the Shining and Reflecting Effect

According to the known reflecting principle, the tiny glass beads will send any light that makes it through them right back where it came from. Therefore, the following approaches can be used to examine the reflecting effect:

Method 1:

Using the video mode and flashlight on your phone’s camera app, inspect the sample from a comfortable distance (around arm’s length).

Method 2:

Take a picture of the sample while holding your phone at arm’s length, using the camera’s flash and photo mode.

How to Recover Reflective Fabric for Garment Production?

- Keep out of direct sunlight and in a cool, dry, well-ventilated area. It would be best to store them where the temperature never rises over 80 degrees, and the humidity never rises beyond 70%.

- Don’t use acid or alkali on reflective cloth. Do not leave something to soak in a solution that is too acidic or too alkaline for too long.

- A textile manufacturer should not use an air conditioner for water cooling. Make careful to give the fabric enough time to dry after dampening or steam ironing.

- Wearing gloves during production can prevent flaws. Meanwhile, reflecting materials should be maintained away from machine oil and other corrosive substances.

How Should Reflective Material Be Cleaned?

Here are a few tips to keep your reflective clothes in good condition for longer:

- Use a mild detergent, but no bleach or fabric softener when machine washing.

- Don’t wash reflective materials with work pants or other rugged apparel. A rough surface can wear away the reflective fabric’s tiny glass beads.

- Line-dry reflective items. Machine drying is an option, but the goods should be removed immediately. The increased temperature may damage the reflective fabric.