Aluminum-forged components combine the inherent lightweight qualities of aluminum with precision forging-derived resilience to create the pinnacle of advanced metallurgy. To achieve superior strength-to-weight ratios, aluminum is subjected to intense pressure during either open-die or closed-die forging.

Larger, more complex structures work well with the open-die method, whereas smaller, more complex components work best with closed-die technology. In addition to ensuring uniformity and close tolerances, this forging improves mechanical qualities like tensile strength.

Encapsulating the future of durable, lightweight engineering, aluminum forged components are widely used in aerospace for structural elements, automotive for transmission and suspension parts, and industrial machinery for gears and rods. They represent a transformative synergy between material science and manufacturing precision.

Applications of Aluminum-Forged Components

Forged aluminum components are utilized in many different industries due to the benefits of aluminum, which include its low weight, resistance to corrosion, and high strength-to-weight ratio. Forging is a manufacturing process that shapes metal using compressive forces, usually applied with a hammer or die. Some common applications for components composed of forged aluminum are as follows:

Aerospace Sector:

Aluminum-forged components find widespread application in the aerospace industry, where weight is critical. Because aluminum gains remarkable strength during the forging process, manufacturers can create lightweight but durable aircraft components. Aluminum forgings play a major role in the overall effectiveness and safety of aircraft, from complex parts like landing gear components to structural elements like wing spars.

Automotive Industry:

Aluminum forged parts are popular in the automotive industry because they can lower vehicle weight without sacrificing structural integrity. Aluminum is frequently forged into engine components, suspension parts, and wheel hubs to improve overall performance and fuel efficiency. Aluminum is also a great material for components exposed to high temperatures, like brake calipers, because of its superior heat dissipation qualities.

Applications in the Marine Sector:

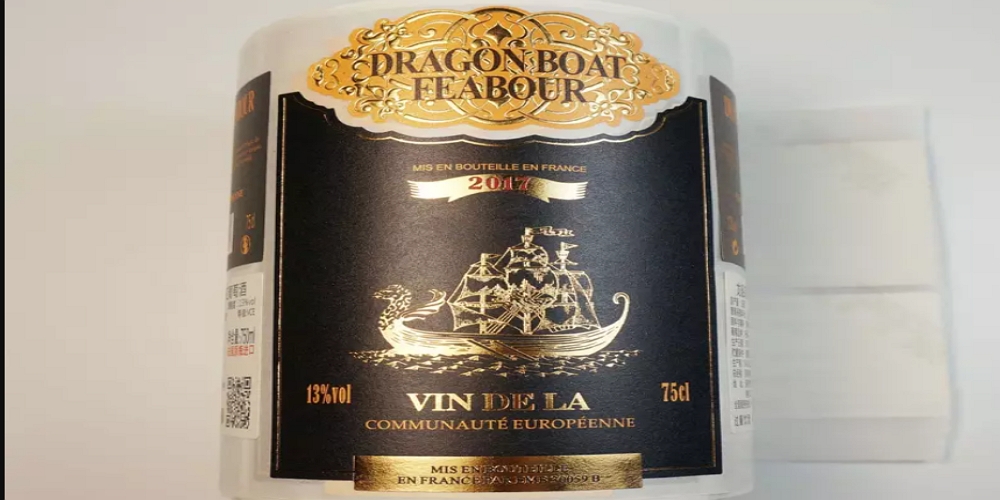

Because it doesn’t corrode easily, aluminum is the material of choice for maritime applications. In the shipbuilding industry, forged aluminum components are widely utilized because they must withstand harsh environmental conditions and saltwater exposure. Aluminum forgings’ lightweight and resistance to corrosion make them useful for parts like ship propellers, hull structures, and navigation systems.

Armaments for Defense and the Military:

Forged aluminum parts are essential in the defense industry, where toughness, longevity, and mass are vital considerations. The military uses aluminum forgings to improve performance and maintain equipment’s agility and maneuverability in everything from armored vehicle parts to missile components.

Energy Industry:

The energy sector, which includes both renewable and conventional energy sources, uses aluminum-forged parts in a variety of ways. Aluminum forgings are used in transmission systems and turbine parts in the power generation industry. Furthermore, because aluminum is lightweight, it increases efficiency in wind turbines, where it is essential to minimize weight at the top of the structure for best performance.

Oil and Gas Industry:

Aluminum forgings are essential to drilling instruments and apparatus used in the oil and gas sector. Tough environments can benefit from their strength and resistance to corrosion. These elements raise the drilling operations’ dependability and efficiency, which raises overall productivity and safety standards in the sector.

Recreation and Sports:

The use of aluminum-forged components in the production of golf clubs, bicycles, and other sports equipment benefits the sports and recreation industry. Aluminum is the perfect material for these applications because of its strength and lightweight, which improves performance and maneuverability.

Technology and Consumer Products:

Heat sinks, casings, and other parts needing a balance between strength and thermal conductivity are made by the electronics industry using aluminum-forged components. Because aluminum is lightweight, it is also advantageous when making consumer goods like laptops and smartphones, where it is important to reduce weight without sacrificing durability.

Conclusion

Because of their exceptional strength, lightweight, and corrosion resistance, aluminum forged components have become essential in many different industries. Across a wide range of applications, including consumer goods, military uses, and the skies and seas, aluminum forgings’ adaptability fosters efficiency and innovation. As manufacturing techniques and technology progress, aluminum-forged components will probably become more and more important in determining the direction of various industries.