When you are in the market for a new die-cast manufacturer, it can be difficult to know who the best fit for your needs is. There are many different factors to consider, and it’s important to find a manufacturer that will meet your expectations in terms of delivery span, quality, and cost. In this article, we will discuss some of the key things to look for when choosing a die casting manufacturer. So, if you’re ready to start hiring around for a new die-cast partner, read on!

Factors to Consider While Choosing a Die Cast Manufacturer

Following are some of the most important factors that you should keep in mind while looking for manufacturers in the hopes that they will meet your needs.

Cost

Sort out what you want in terms of size as well as complexity, and then do your research about the particular cast’s price range. Make your own budget accordingly, and then choose the manufacturer that falls in your price range and is affordable for you. Do keep a little flexibility in your budget so that finding a good manufacturer is somewhat an easy task for you.

Experience

When hunting for a manufacturer, do complete research about their working period, their availability, and reputation in the market. Take reviews from companies who have worked with them. Last but not least, check how many years’ worth of experience that particular manufacturer has. More experience would likely mean fewer chances of mistakes and a good quality product.

Quality of material

Check out a pre-made sample material first and focus on the quality of the material. Make sure to specifically look at the things you are very conscious about and cannot compromise on at all, like:

- Corrosion resistance

- Strength and hardness

- Thermal conductivity

- Electrical conductivity

- EMI/RFI shielding properties

Delivery time

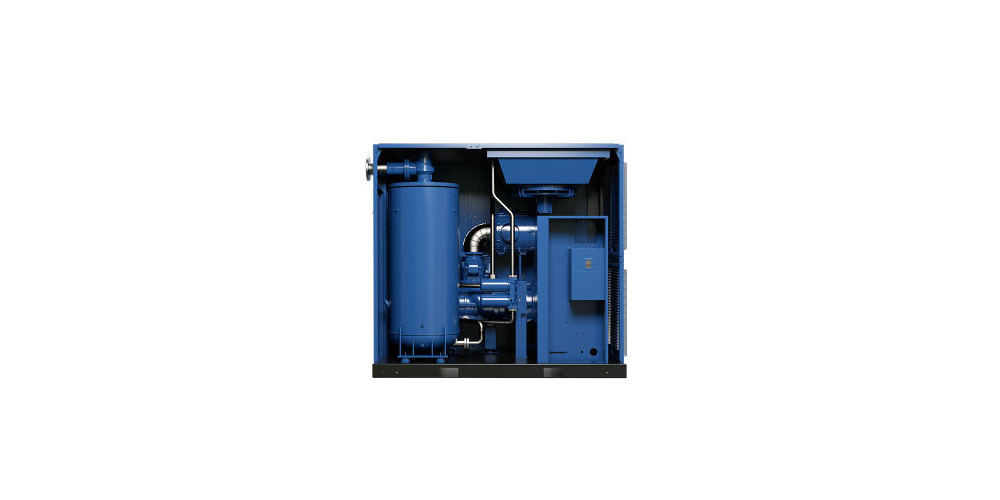

This factor is very important for smooth business between you and the manufacturer. So, make sure to talk about delivery timings so that you get your product timely. Also, take a look at their production capacity annually so that your needs are met in time.

Testing facilities

Take a look at your manufacturer’s workplace and note that they have enough high-tech machines, top-notch facilities, and the necessary laboratories listed below to provide you with the high-quality product you demand.

- Testing rigs

- Metallurgic labs

- X-ray testing

- CMM

- TMM

- Radiography

- Tomography

- Humidity and temperature monitoring

- Leak testing machines

Summing-Up

First off, decide what type of die casting you need. There are many different types, each with its own benefits and drawbacks. Do some research to figure out which one is best for your project. Secondly, ask around for recommendations from other businesses that have used die casters in the past. Chances are, someone you might know has already worked with a manufacturer and can give you some good advice. Lastly, take into consideration the cost of the service. Die casting can be expensive, so make sure you’re getting what you expect.